Akwai nau'ikan gilashin lebur guda uku a duniya a yau: zane mai lebur, hanyar iyo da kuma kalandar. Gilashin da ke kan ruwa, wanda ke da fiye da kashi 90% na jimillar samar da gilashin a halin yanzu, shine ainihin kayan gini a cikin gilashin gine-ginen duniya. An kafa tsarin samar da gilashin ruwa a cikin 1952, wanda ya kafa ma'auni na duniya don samar da gilashi mai inganci. Tsarin gilashin da ke iyo ya ƙunshi manyan matakai guda biyar:

● sinadaran

● narkewa

● kafawa da sutura

● damuwa

● yankan da tattarawa

Sinadaran

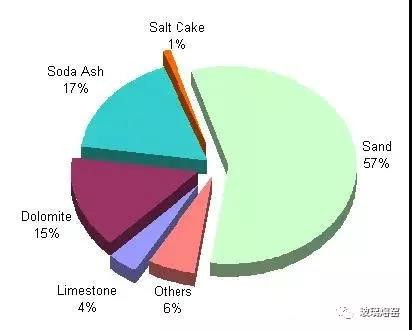

Batching shine mataki na farko, wanda ke shirya albarkatun kasa don narkewa. Danyen kayan sun hada da yashi, dolomite, limestone, soda ash da mirabilite, wadanda ake jigilar su ta mota ko jirgin kasa. Ana adana waɗannan albarkatun ƙasa a cikin ɗakin batching. Akwai silos, hoppers, bel na jigilar kaya, chutes, masu tara ƙura da tsarin kulawa masu mahimmanci a cikin ɗakin kayan, waɗanda ke sarrafa jigilar albarkatun ƙasa da hada kayan batch. Tun daga lokacin da aka kai kayan da aka kawo zuwa dakin kayan, suna motsawa akai-akai.

A cikin ɗakin batching, dogon bel mai ɗaukar nauyi yana ci gaba da jigilar albarkatun ƙasa daga silo na albarkatun ƙasa daban-daban zuwa Layer lif ɗin guga bisa tsari, sannan a aika su zuwa na'urar auna don duba nauyinsu. Gilashin da aka sake yin fa'ida ko dawo da layin samarwa za a ƙara zuwa waɗannan sinadarai. Kowane rukuni ya ƙunshi kusan 10-30% fashe gilashi. Ana ƙara busassun kayan a cikin mahaɗin kuma a haɗa su cikin tsari. Ana aika da batch ɗin gauraye daga ɗakin batching zuwa silo na kiln don adanawa ta bel ɗin jigilar kaya, sannan a saka shi cikin tanderu a ƙimar sarrafawa ta mai ciyarwa.

Haɗin Gilashin Na Musamman

Cullet Yard

Ciyar da Kayan Gaɗaɗɗen Raw A cikin Mashigar Tanderu Har zuwa Digiri 1650 Tare da Hopper

Narkewa

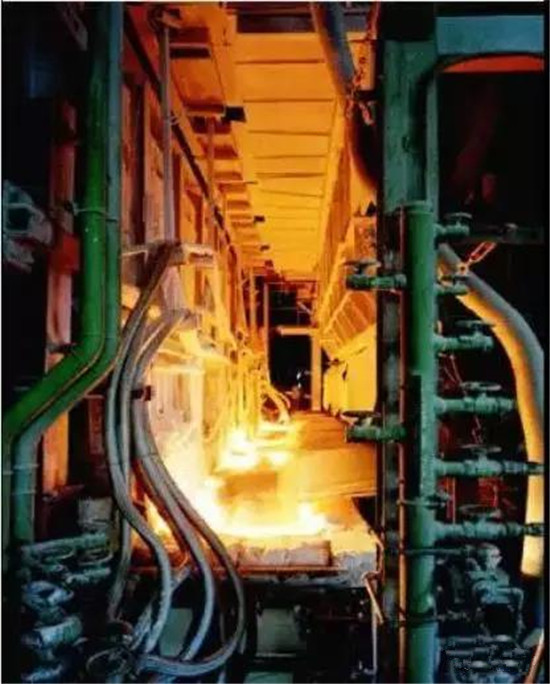

Tanderu na yau da kullun ita ce tanderun wuta mai jujjuyawar wuta tare da na'urori masu sabuntawa guda shida, faɗin kusan mita 25 da faɗin mita 62, tare da ikon samar da tan 500 a kullun. Babban sassan tanderun sune narkewa pool / bayyanawa, wurin aiki, regenerator da ƙaramin tanderu. Kamar yadda aka nuna a cikin hoto na 4, an yi shi da kayan gyarawa na musamman kuma yana da tsarin karfe akan firam na waje. Ana aika batch ɗin zuwa wurin narkar da tanderun ta mai ciyarwa, kuma ana dumama tafkin zuwa 1650 ℃ ta bindigar feshin iskar gas.

Gilashin narkakkar yana gudana daga wurin narkewa zuwa yankin wuyansa ta wurin mai bayyanawa kuma ana motsa shi daidai. Daga nan sai ya zubo cikin sashin aiki kuma a hankali ya yi sanyi zuwa kusan digiri 1100 don sa ya kai ga danko daidai kafin ya isa wurin wankan kwano.

Samar da Shafi

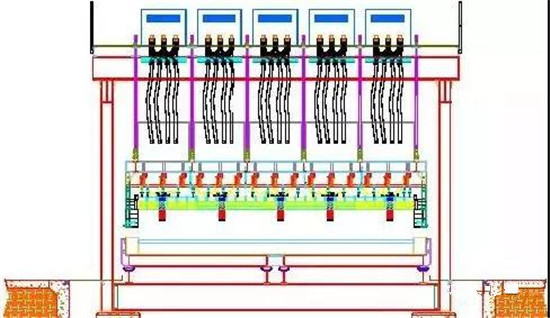

Hanyar samar da gilashin ruwa mai haske a cikin farantin gilashi shine tsari na magudin inji bisa ga dabi'ar dabi'ar kayan, kuma kauri na wannan abu shine 6.88 mm. Gilashin ruwa yana gudana daga cikin tanderun ta hanyar tashar tashar, kuma ana sarrafa kwararar ta ta hanyar daidaitacce kofa da ake kira rago, wanda ke zurfin ± 0.15 mm cikin gilashin ruwa. Yana iyo a kan narkakkar gwangwani - don haka sunan gilashin iyo. Gilashi da kwano ba sa amsawa da juna kuma ana iya raba su; Juriyar junansu a cikin sigar kwayoyin halitta yana sa gilashin ya zama santsi.

Wanka naúrar ce da aka hatimce a cikin yanayi mai sarrafa nitrogen da hydrogen. Ya hada da goyon bayan karfe, saman da kasa bawo, refractories, tin da dumama abubuwa, rage yanayi, zafin jiki na'urori masu auna sigina, kwamfuta tsarin kula da tsarin, game da 8 mita fadi da 60 mita tsawo, da kuma samar line gudun iya isa 25 mita / minti. Wankin dandali ya ƙunshi kusan tan 200 na tsaftataccen tin, tare da matsakaicin zafin jiki na 800 ℃. Lokacin da gilashin ya samar da siriri a ƙarshen mashigan wanka na tin, ana kiransa farantin gilashin, kuma jerin masu jan baki masu daidaitawa suna aiki a bangarorin biyu. Mai aiki yana amfani da shirin sarrafawa don saita saurin murƙushe kiln da injin zana gefen. Kauri daga cikin gilashin farantin iya zama tsakanin 0.55 da kuma 25 mm. Ana amfani da ɓangaren dumama na sama don sarrafa zafin gilashin. Yayin da farantin gilashin ke ci gaba da gudana ta cikin wankan kwano, zafin farantin gilashin zai ragu sannu a hankali, yana mai da gilashin lebur da layi ɗaya. A wannan lokaci, za a iya amfani da acuracoat ® A kan layi na fim mai nunawa, ƙananan e fim, fim ɗin sarrafa hasken rana, fim din hoto da kuma tsabtace kai akan kayan aikin pyrolysis CVD. A wannan lokacin, gilashin yana shirye don kwantar da hankali.

Sashin Giciye Bath

Ana Yada Gilashin A Cikin Bakin Baki Akan Narkakken Tin, A Keɓe shi Daga Tin, kuma a Ƙirƙiri shi cikin Faranti.

Abubuwan dumama rataye suna ba da wadataccen zafi, kuma faɗin da kauri na gilashin ana sarrafa su ta hanyar saurin gudu da kusurwar jan ƙarfe.

Annealing

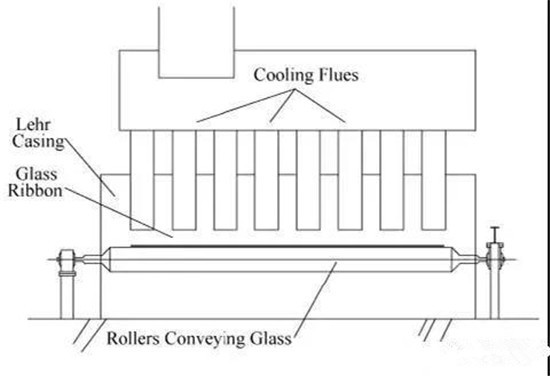

Lokacin da gilashin da aka kafa ya fita daga wanka na kwano, zafin gilashin shine 600 ℃. Idan farantin gilashin ya sanyaya a cikin yanayi, saman gilashin zai yi sanyi da sauri fiye da na cikin gilashin, wanda zai haifar da matsa lamba mai tsanani da damuwa na ciki na gilashin gilashi.

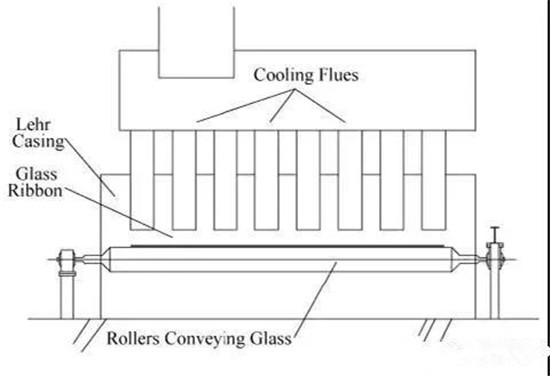

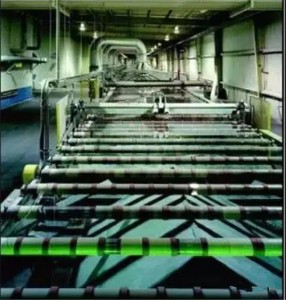

Sashen Annealing Killn

Tsarin dumama gilashin kafin da bayan gyare-gyaren kuma shine tsarin samuwar damuwa na ciki. Sabili da haka, wajibi ne don sarrafa zafi don rage yawan zafin jiki na gilashin zuwa yanayin zafi, wato, annealing. A haƙiƙa, ana gudanar da aikin saɓo a cikin kaskon zafin jiki wanda aka riga aka saita (duba hoto na 7) faɗin mita 6 da tsayin mita 120. Wurin murɗawa ya haɗa da abubuwan dumama da ke sarrafa wutar lantarki da magoya baya don kiyaye yanayin zafin rarraba faranti na gilashi.

Sakamakon tsari na annealing shine cewa an sanyaya gilashin a hankali zuwa zafin jiki ba tare da danniya ko damuwa na wucin gadi ba.

Yanke Da Marufi

Ana jigilar faranti na gilashin da aka sanyaya ta hanyar annealing kiln zuwa yanki mai yankewa ta hanyar abin nadi da aka haɗa tare da tsarin tuki na annealing kiln. Gilashin ya wuce tsarin dubawa na kan layi don kawar da duk wani lahani, kuma an yanke shi tare da shingen yankan lu'u-lu'u don cire gefen gilashin (an sake yin amfani da kayan gefen kamar gilashin da ya karye). Sa'an nan kuma yanke shi zuwa girman da abokin ciniki ke bukata. Ana yayyafa saman gilashin da matsakaicin foda, ta yadda za a iya tara faranti na gilashin a adana su don guje wa mannewa tare ko tatsa. Sa'an nan kuma, an raba faranti na gilashin marasa lahani zuwa marufi don tattarawa ta hanyar injina ko na atomatik, kuma a tura su cikin sito don ajiya ko jigilar kaya ga abokan ciniki.

Bayan farantin gilashin ya bar aninging na aneal, farantin gilashin cikakke kuma ya koma yankin sanyaya don ci gaba da rage zafin jiki